Through-hole alice with knob

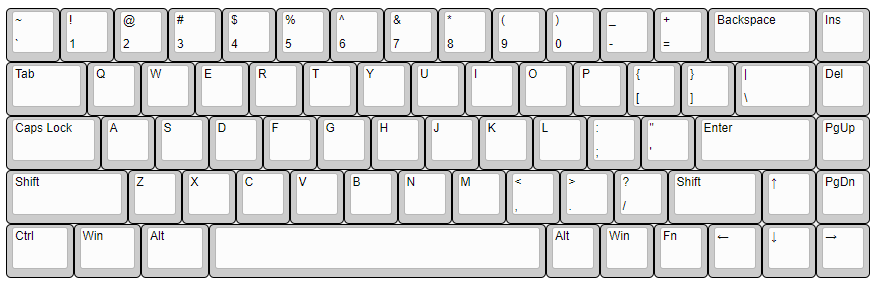

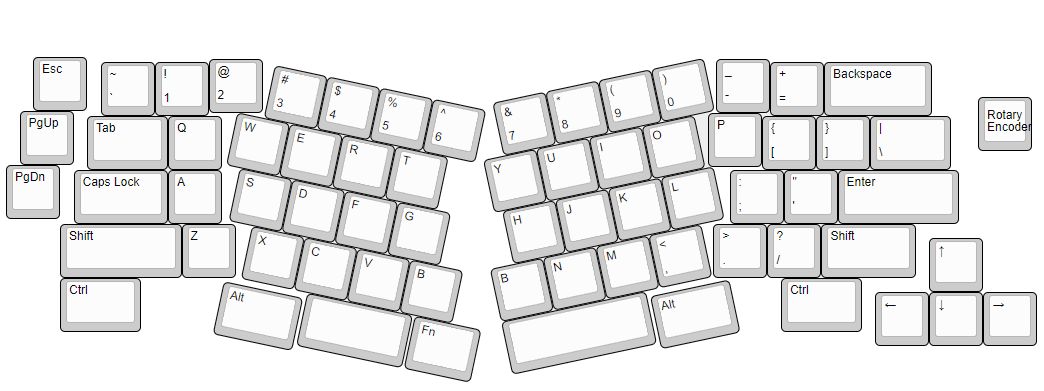

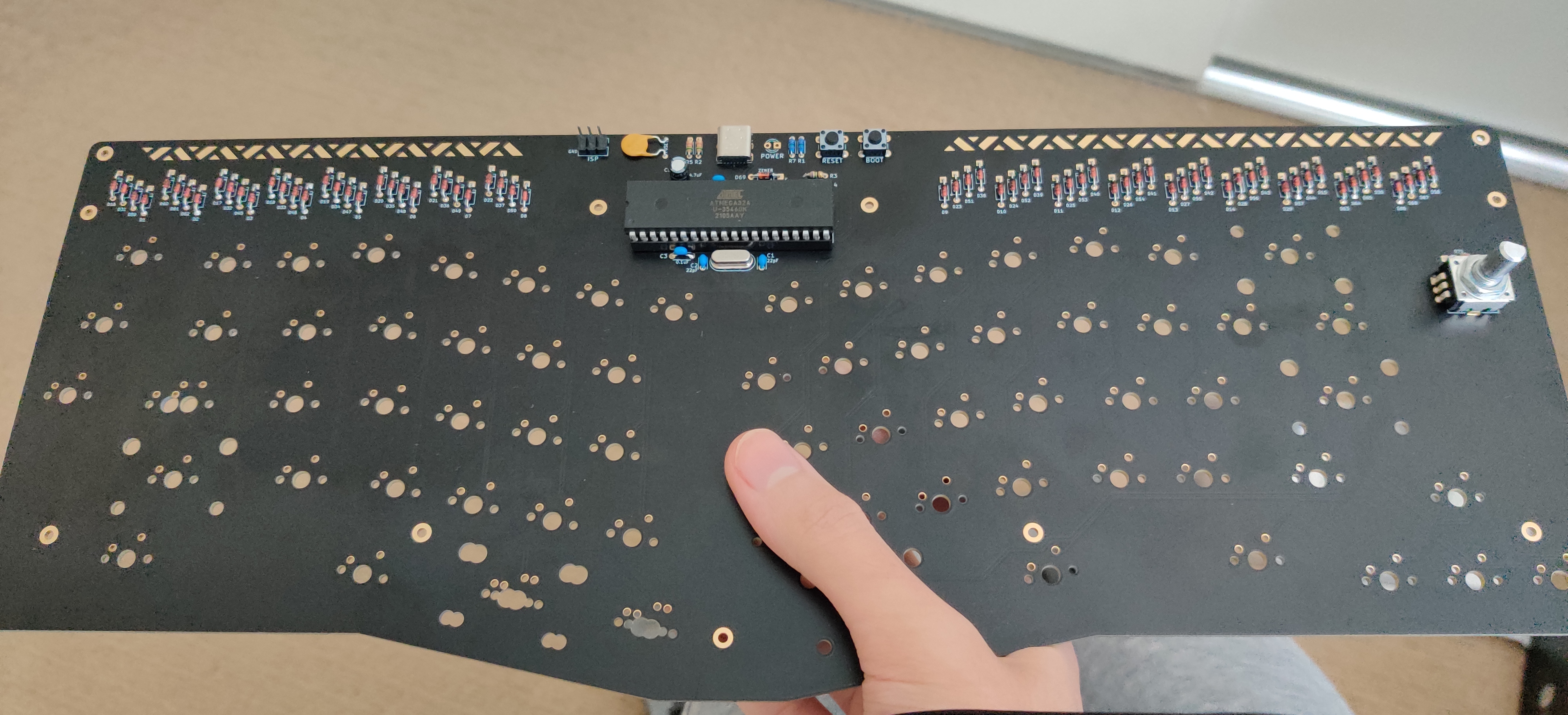

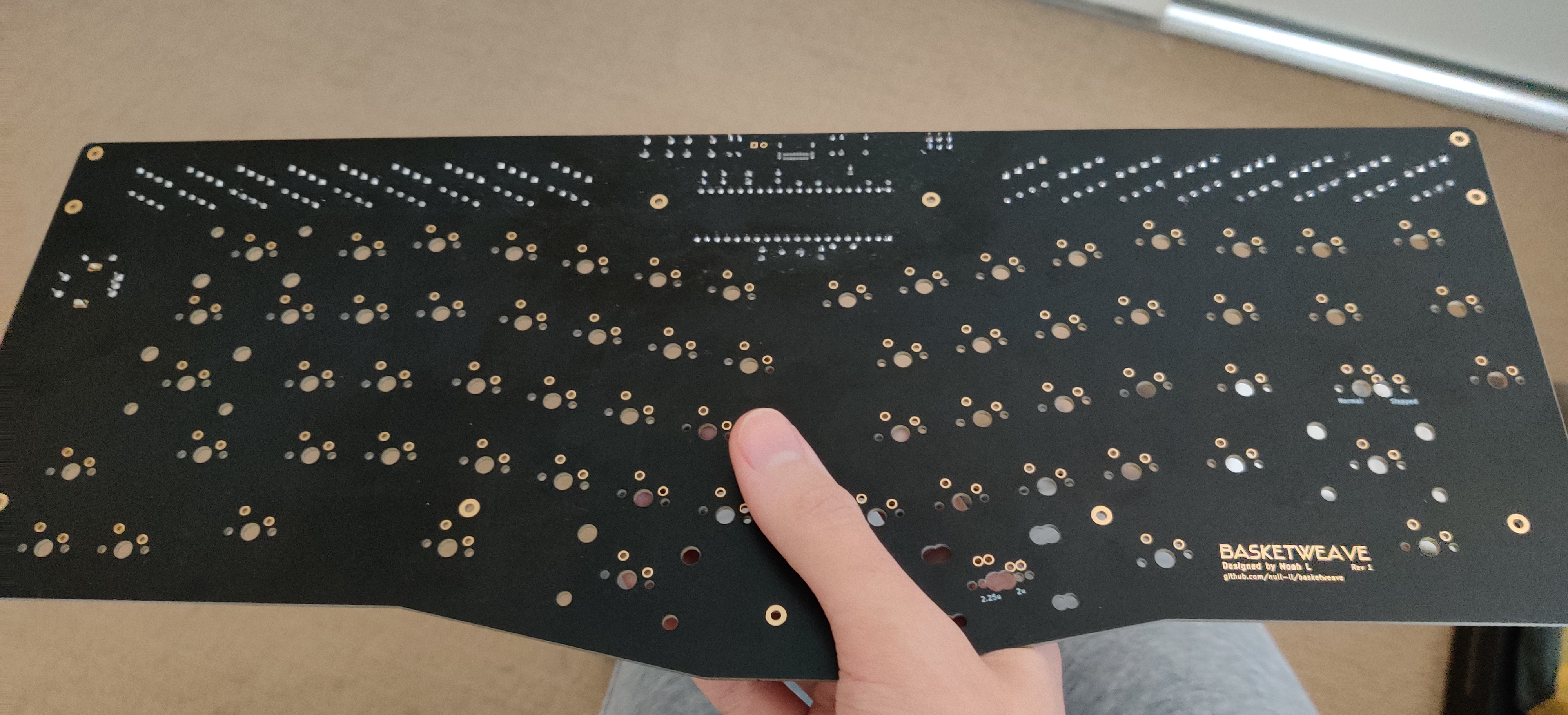

The Basketweave is an Alice keyboard with arrow keys and a knob manufactured by Clackery. The Alice layout is an ergonomic variation of the 60/65% keyboard that splits the region of the keys in half and angles the sections downward. The philosophy of this layout is that the angled sections increase the distance between the user's wrists during use, which reduces wrist strain.

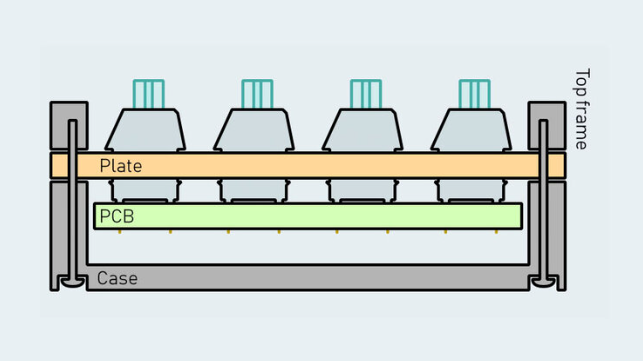

The mounting style of the Basketweave is known as a "sandwich" mount. This mounting style involves the plate of the keyboard being "sandwiched" between the top and bottom halves of the keyboard's housing. This mounting style typically offers a stiffer typing experience compared to other mounts.

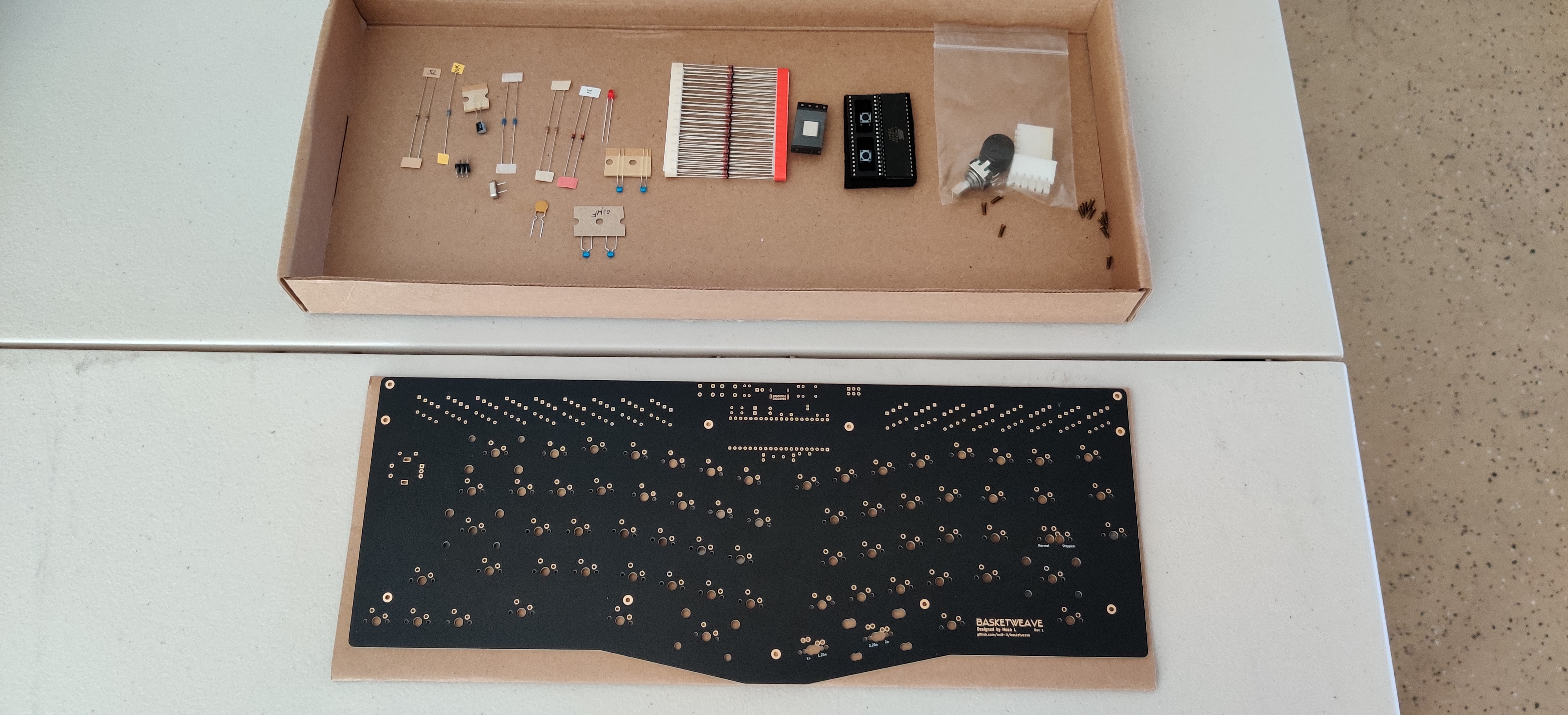

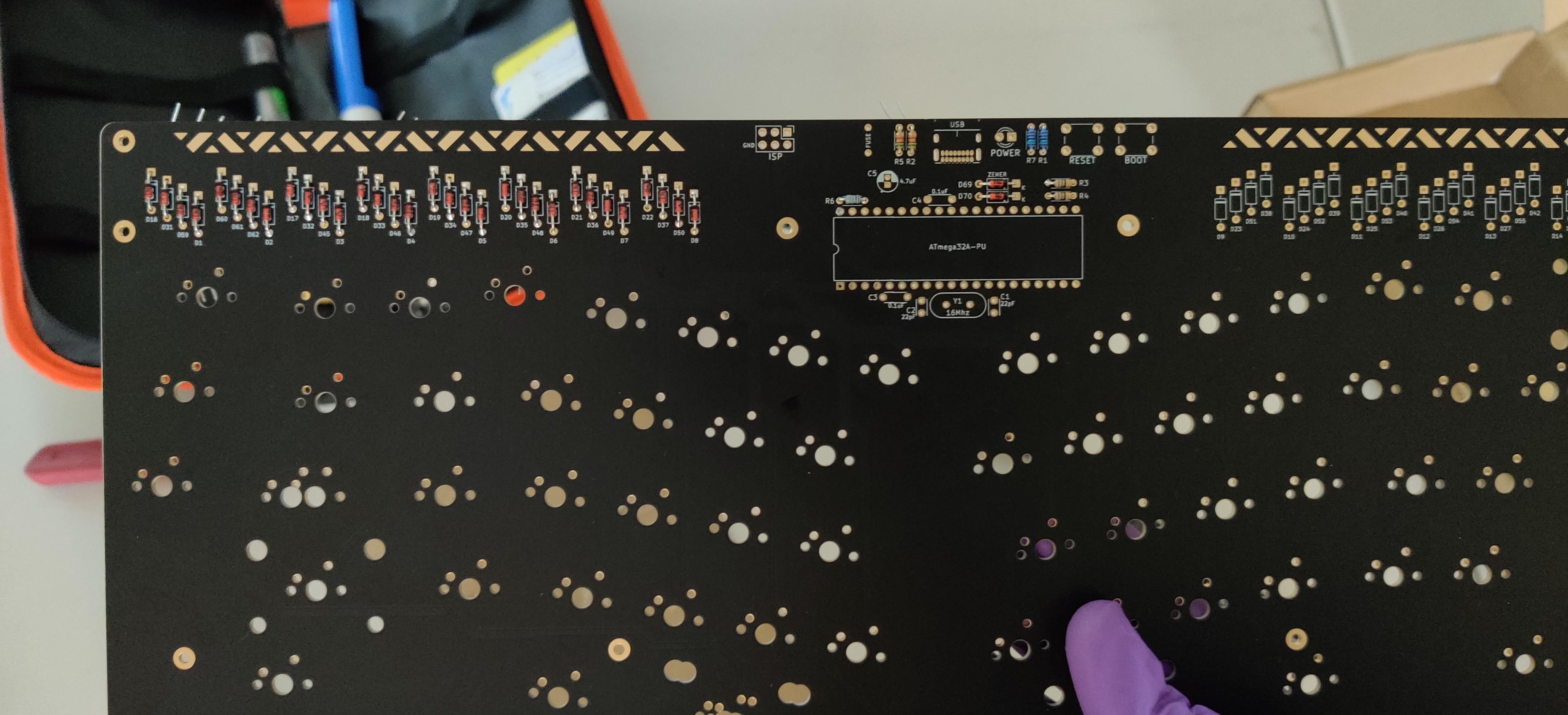

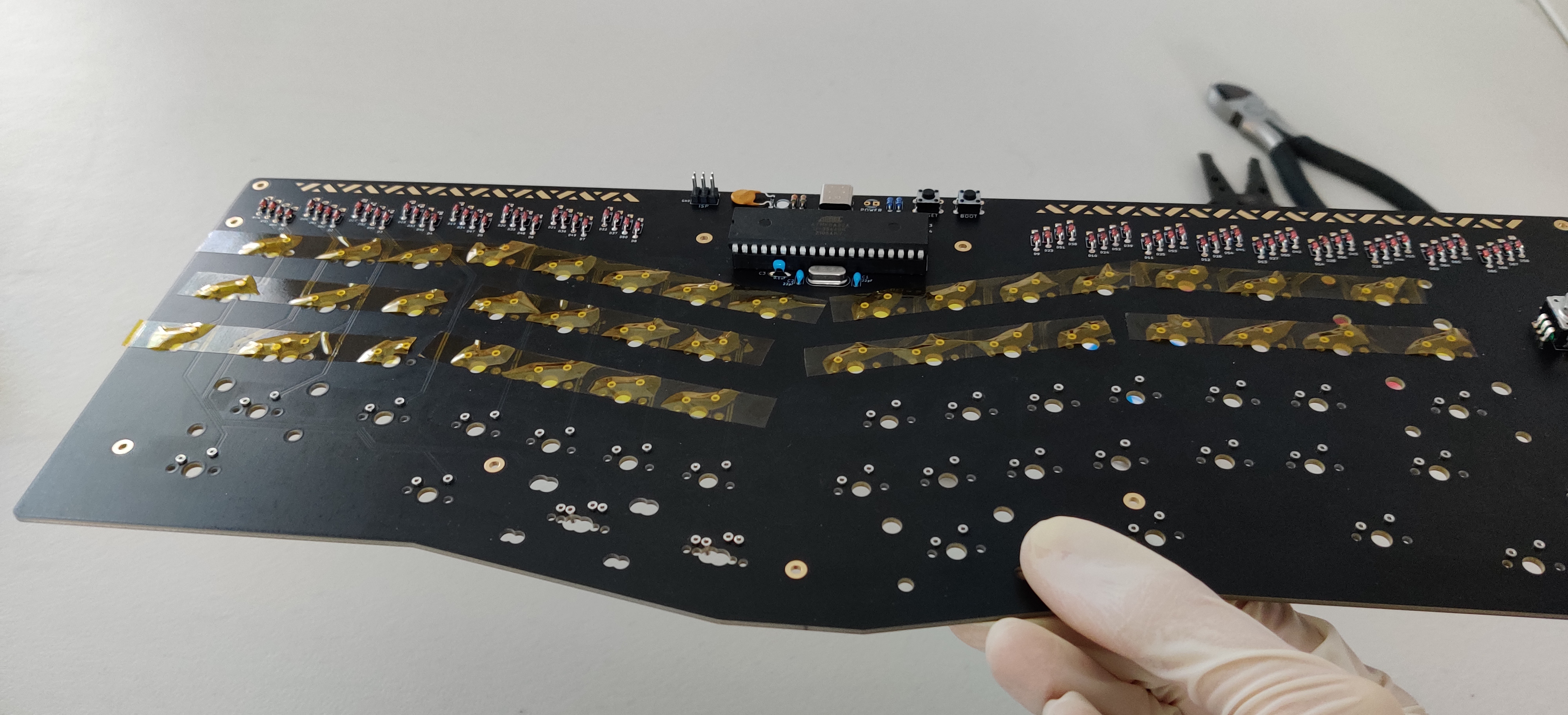

The Basketweave is sold as a kit consisting of a blank PCB and various components that are to be soldered onto it. Custom mechanical keyboards are not typically sold like this, and often arrive with PCBs that have all of their components already soldered. However, the Basketweave is a small project that was coordinated by a single person, rather than a corporation or factory. Selling the kits this way greatly reduces the cost and labor which is also reflected in its final retail price.

The components that come with the Basketweave include various diodes, capacitors, fuses, and resistors.

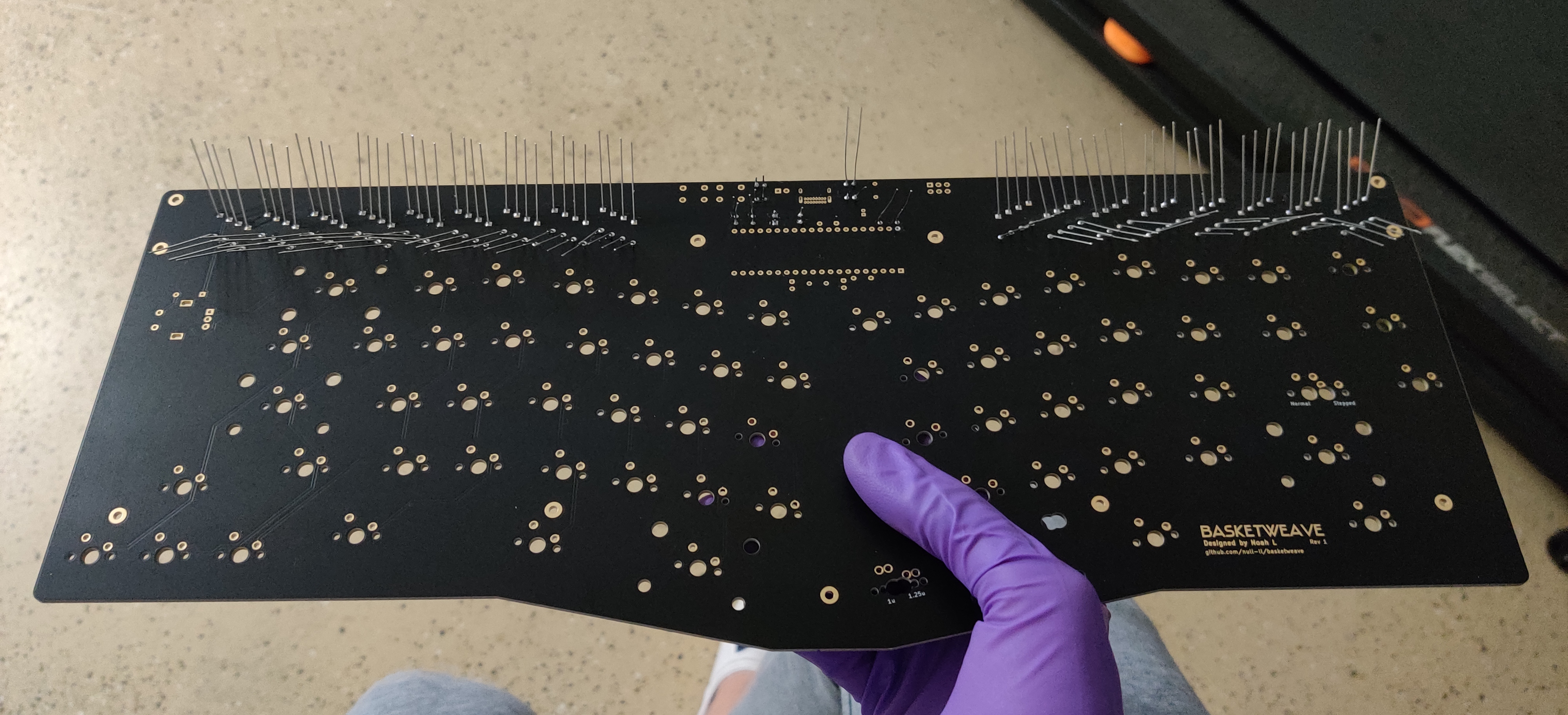

Additionally, the components to solder onto the PCB are "through-hole", meaning that the devices have legs that are passed through the sockets of the PCB when soldered and cut once the joints are made behind the PCB. These components are not common among the majority of keyboards which use "surface-mount" components that are soldered to the front, or surface, of the PCB.

Soldering all of the components of the Basketweave involves soldering many joints and also one instance of drag soldering in order to install the USB-C connector.

The PCB has also been made "hotswappable" by soldering 0305 Mill-Max sockets in each of the switch sockets. This allows for switches to be installed and uninstalled by simply inserting the switches into the PCB as opposed to soldering and desoldering them.

The plate foam is a sheet that is placed between the top of the PCB and the bottom of the plate. The purpose of this foam is to reduce the reverb within the keyboard during use. However, this foam can reduce the flexibility of the keyboard as well as the tone of each keypress. Since this keyboard uses a sandwich mount, there is already minimal flexibility, making the consequences of plate foam negligible.

The Basketweave is a keyboard that rewards those who put the time and effort into assembling it. The assembly of the keyboard was both exciting and stressful as there was not a clear way to know I assembled it correctly until it was finished. The case is made entirely out of acrylic, and has a glossy finish that looks stunning once assembled. Surprisingly enough, I adjusted to the layout quickly, typing comfortably after an hour of use. The Basketweave is a tall keyboard, having a front height of 22mm. This made wrist strain a primary concern for me, but I was pleasantly surpised by its absence due to the ergonomic layout.